Inspection guide to keep your line running smoothly

Understanding the Relevance of Stretch Wrapper Repair for Optimal Product Packaging Performance

Stretch wrappers play an essential function in ensuring packaging performance throughout various markets. However, their efficiency can be compromised by common issues that emerge with time. Ignoring fixings can lead to substantial functional setbacks and financial consequences. Comprehending the signs that show upkeep is needed is vital for sustaining productivity. This raises the questions of how business can properly handle their stretch wrapper upkeep to avoid interruptions and maintain high quality.

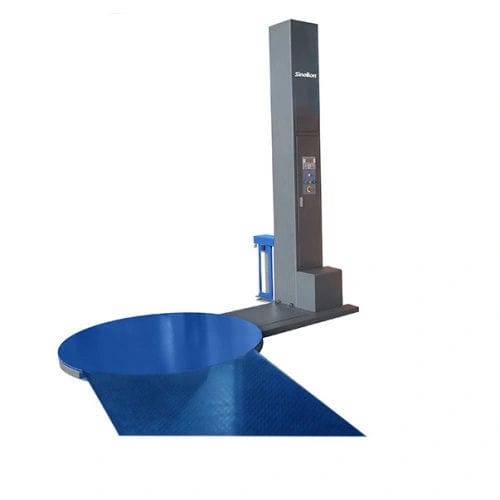

The Function of Stretch Wrappers in Packaging Effectiveness

Stretch wrappers act as necessary elements in the product packaging process, significantly boosting performance in various sectors. These equipments make use of stretch film to secure products on pallets, lessening movement throughout transportation and storage space. By firmly covering items, stretch wrappers shield them from contamination, damage, and wetness, ensuring they reach their location intact.In enhancement to securing products, these wrappers enhance the packaging process. Automated stretch covering systems considerably enhance output, minimizing time and labor costs associated with manual packaging. The consistent application of tension in the covering procedure likewise optimizes product use, causing cost savings and minimized waste.Moreover, stretch wrappers can be gotten used to suit various product shapes and sizes, offering versatility in packaging procedures. This adaptability allows firms to boost their overall productivity, maintain high standards of quality assurance, and improve client complete satisfaction via trustworthy delivery of well-packaged products.

Common Concerns That Affect Stretch Wrapper Efficiency

Packaging performance can be significantly impeded by different problems that influence stretch wrapper performance. One typical issue is irregular stress throughout the covering procedure, which can result in inadequate load security (stretch wrapper repair). In addition, malfunctioning sensing units may stop working to detect the load elevation, causing improper covering and squandered materials. Damage on components such as rollers and belts can additionally disrupt the smooth procedure of the machine, creating hold-ups and potential damage to products. An additional concern is the high quality of the stretch movie itself; poor materials can tear conveniently or fall short to adhere appropriately to the lots. Routine upkeep is vital to recognize and remedy these issues before they rise. Inevitably, making sure peak performance of stretch wrappers not just enhances product packaging efficiency but also maintains item honesty throughout the supply chain. Resolving these usual problems is crucial for maintaining efficient product packaging procedures

The Financial Influence of Ignoring Stretch Wrapper Repairs

Ignoring stretch wrapper repair work can result in significant financial consequences for companies. Boosted product packaging expenses and prolonged downtime cause productivity loss, eventually impacting the bottom line. Resolving these repair services immediately is important to keep functional efficiency and cost-effectiveness.

Raised Packaging Expenses

Gradually, stopping working to deal with necessary repairs on stretch wrappers can cause substantial monetary repercussions for organizations. As devices malfunctions or uses down, packaging efficiency reduces, causing raised material use. This can manifest as the demand for more stretch movie to protect loads adequately, increasing total product packaging costs. Furthermore, poorly covered products may lead to harm during transportation, necessitating extra costs for replacements and client compensation. Companies may additionally locate themselves purchasing expedited shipping to change harmed goods quickly, which better strains their budgets. Inevitably, disregarding stretch wrapper repairs not just boosts instant product packaging prices however can additionally contribute to long-lasting economic instability, affecting productivity and competitiveness in the marketplace.

Downtime and Performance Loss

Downtime positions a considerable threat to operational performance in any service relying on stretch wrappers. When these devices experience malfunctions, manufacturing stops, bring about considerable performance losses. Each hour of inactivity not just threatens process however also increases labor prices as workers stay still. In addition, postponed shipments can harm consumer relationships and tarnish a company's online reputation. The monetary ramifications are profound; neglecting timely fixings can bring about advancing losses that much surpass the price of upkeep. By prioritizing stretch wrapper maintenance, companies can lessen downtime, boost performance, and assurance regular operational flow. Ultimately, buying routine repair work safeguards earnings and maintains affordable advantage in a demanding market.

Signs That Your Stretch Wrapper Demands Upkeep

How can one inform when a stretch wrapper needs maintenance? Several signs indicate that a stretch wrapper might not be operating at peak effectiveness. First, irregular covering tension might result in loosened or excessively tight tons, compromising bundle security. Furthermore, if the maker produces extreme noise or resonances during operation, it might indicate used components that need attention. Operators must likewise observe the film's application; if there are creases or tears, this could indicate concerns with the movie carriage or the stress settings.Frequent mistake messages or alarms throughout procedure are another clear indicator of possible troubles. If the cycle time boosts, it may recommend that the stretch wrapper is having a hard time to perform at its ideal. Routinely looking for these indications can aid guarantee that maintenance is set up before even more considerable issues emerge, inevitably adding to the general performance of the product packaging procedure.

Benefits of Normal Stretch Wrapper Upkeep

Normal maintenance of stretch wrappers uses significant advantages for product packaging procedures. It not only expands the lifespan of the devices yet also minimizes downtime expenses and boosts the total quality of packaging. By focusing on maintenance, firms can boost performance and assurance constant efficiency in their product packaging processes.

Increased Devices Life-span

Keeping a stretch wrapper not just enhances product packaging performance but likewise greatly extends the devices's life-span. Regular upkeep techniques, such as cleaning, lubrication, and timely replacement of worn components, stop premature damage, guaranteeing that the equipment runs at peak performance. By addressing small issues prior to they escalate, drivers can avoid considerable damage that could result in pricey repair services or the requirement for a complete replacement. On top of that, constant maintenance cultivates a better understanding of the device's operational limits, permitting optimal use without overexertion. This proactive method inevitably contributes to a much longer functional life for the stretch wrapper, making best use of the roi for businesses and guaranteeing reliability in their product packaging processes.

Decreased Downtime Expenses

Efficient operations rest on decreasing downtime, specifically in high-demand product packaging settings. Routine maintenance of stretch wrappers significantly reduces the chance of unforeseen break downs, which can cause expensive manufacturing stops. By proactively attending to small problems before pop over to this site they rise into major failures, companies can ensure that their packaging lines remain functional. This preventative approach not just conserves time however likewise minimizes labor costs related to emergency situation repair work and unplanned downtime. On top of that, regular upkeep permits better organizing of repair work, causing less disruption throughout top operational hours. Because of this, the general productivity of the product packaging process boosts, converting into better performance and expense financial savings for the organization. Routine stretch wrapper upkeep is essential for keeping functional consistency in affordable markets.

Improved Product Packaging High Quality

When stretch wrappers are appropriately preserved, the quality of packaging can significantly boost, making certain that products are securely covered and secured during transportation and storage. Regular upkeep assists in recognizing and remedying possible issues before they intensify, such as imbalance or use on parts, which can endanger the covering procedure. This proactive method not only improves the integrity of the wrapped items however likewise reduces the threat of damage brought on by environmental variables. Furthermore, constantly properly maintained stretch wrappers add to uniformity in product packaging, guaranteeing that each lots meets the required criteria. Eventually, improved product packaging quality leads to enhanced client contentment, lowered return prices, and a stronger online reputation for integrity, every one of which are essential for sustained business success.

Selecting the Right Repair Service Service for Your Stretch Wrapper

Selecting the suitable fixing solution for a stretch wrapper is important to maintaining product packaging efficiency and reducing downtime. Businesses need to prioritize services that specialize in stretch wrapper fixings, as these service providers have the required experience and experience. Assessing her explanation the technician's certifications and the company's online reputation can significantly impact fixing quality.Additionally, it is useful to consider the availability of substitute parts and the speed of solution. A dependable fixing solution must not only supply prompt support but additionally supply service warranty options for their job, making sure long-lasting self-confidence in repairs.Furthermore, companies should look for out testimonies and reviews from other clients to assess the service's performance and dependability. Clear communication relating to costs and repair service timelines is additionally crucial in establishing count on. Inevitably, picking the ideal fixing solution can bring about enhanced functional performance, minimized costs, and boosted efficiency for services relying upon stretch wrappers for their product packaging requires.

Best Practices for Stretch Wrapper Upkeep and Durability

Routine upkeep is crucial for making certain the durability and ideal efficiency of stretch wrappers. Consistent inspections must be carried out to identify wear and tear on elements, such as rollers, electric motors, and belts. Lubing relocating components at suggested periods minimizes friction and extends devices life.Furthermore, drivers need to be trained to make use of the equipment properly, as incorrect handling can bring about premature failures. Keeping the office complimentary and clean of debris lowers the risk of mechanical damage and advertises a risk-free working environment.Replacing used or damaged components promptly is vital; this avoids small issues from rising into costly fixings. In addition, maintaining a log of maintenance activities helps track the efficiency and solution history of the stretch wrapper.

Often Asked Concerns

Just How Frequently Should Stretch Wrappers Be Serviced for Ideal Efficiency?

The frequency of servicing stretch wrappers commonly depends on use intensity. Generally, manufacturers recommend inspections every 6 to year, ensuring peak efficiency and lessening unintended downtime via proactive maintenance and prompt repair services.

Can I Do Repair Work on Stretch Wrappers Myself?

The view publisher site individual contemplated whether they can carry out repair work on stretch wrappers themselves. stretch wrapper repair. It was kept in mind that while some minor adjustments could be manageable, professional competence is typically suggested for complicated problems to assure security and functionality

What Components of a Stretch Wrapper Are A Lot Of Prone to Failing?

Stretch wrappers typically experience failures in components such as the movie carriage, drive electric motors, and sensing units. These components are indispensable to the machine's procedure and may need normal maintenance or prompt replacement to assure peak performance.

Exactly How Does Environmental Effect Affect Stretch Wrapper Efficiency?

Ecological aspects, such as moisture and temperature variations, can substantially influence stretch wrapper efficiency. These problems might lead to product deterioration, irregular wrapping tension, and ultimately, decreased performance in the packaging procedure. Regular assessments are necessary.

Are There Certain Brand Names Known for Better Longevity in Stretch Wrappers?